New energy vehicle is driving Anhui’s manufacturing transformation.

Anhui Province’s automobile and new energy vehicle (NEV) production output both leapt to first place in China in the first quarter of 2025, and its automobile exports also ranked first nationwide. For every eight vehicles produced in the country, there is one “made in Anhui,” while one out of every four vehicles exported comes from the province.

When mentioning Anhui, people have traditionally thought of the majestic Huangshan Mountain and lyrical Huangmei Opera. However, today, NEVs, as the province’s leading industry, showcase its impressive progress in driving innovation, ushering in an era of transformation and intelligence in the manufacturing industry.

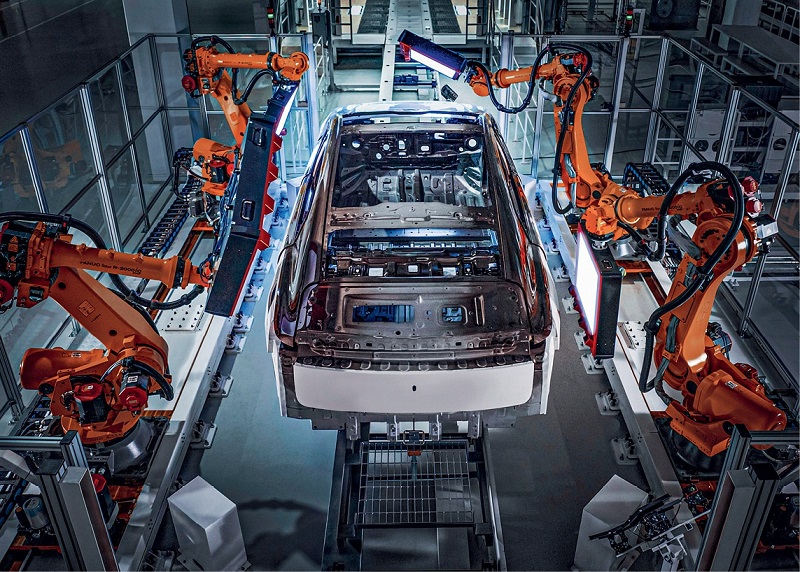

A car body is under AI quality testing inside the Maextro Super Factory.

Overwhelming Momentum

Maextro S800 is a luxury sedan jointly developed by Jianghuai Automobile Group and Huawei. Within just one month of its launch, it has received over 6,500 orders, setting a new record in China’s luxury car market and adding a significant milestone to the history of NEV development.

The Maextro Super Factory is a world-class intelligent factory that integrates digital research and development, low-carbon manufacturing, and brand experience services. Its production line is equipped with over 1,800 intelligent robots, achieving comprehensive automation and digitization of four major processes: stamping, welding, painting, and final assembly. It also supports intelligent flexible customization. Notably, it has reached industry-leading levels of digital twinning at the welding and painting stages. Currently, the factory has an annual production capacity of 200,000 vehicles, with an expected output value reaching RMB 100 billion upon full production.

Adjacent to Hefei Xinqiao International Airport lies the factory of Chinese NEV giant NIO, which features a vast six-storey vehicle storage and retrival platform, with 753 parking spaces. The massive robotic arm can swiftly pick up the “desired” vehicle within one minute and transfer it to the designated workshop.

This platform breaks the limitations of flat garages, allowing for more flexible inventory retrieval. It significantly shortens sorting time while ensuring personalized user choices, greatly enhancing production efficiency.

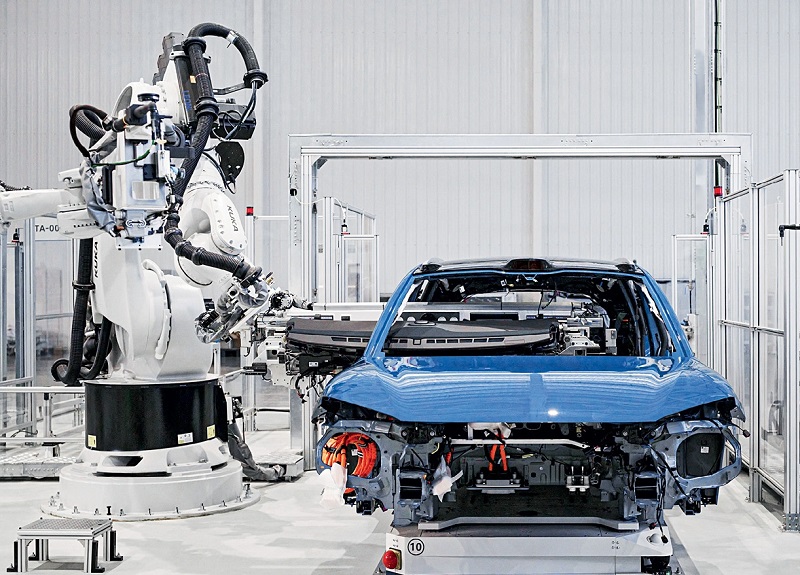

The factory is one of the most advanced factories worldwide in terms of intelligence. Eighty percent of manufacturing here is controlled by AI, and it supports simultaneous production across multiple platforms and vehicle models, achieving a 100-percent automation in the joining process.

NIO’s globally pioneering self-developed production and quality inspection systems have broken the traditional dilemma between large-scale production and personalized customization. The factory was recognized as the Super Automotive Factory by the China Automotive Technology and Research Center, which also granted it the Best Digital Application Award.

China’s 14th Five-Year Plan (2021-2025) clearly states the need to expand strategic emerging industries such as NEVs, accelerate the innovation and application of key core technologies, enhance the capacity for resource assurance, and foster new momentum for industrial development. Anhui, in recent years, has explicitly designated the automotive industry, particularly the NEV sector, as a key area for development, aiming to drive industrial growth through innovation. The goal is to transform the province into a global innovation hub for smart NEVs.

Li Bin, founder and chairman of NIO, stated that with the strong support from Anhui Province, NIO’s operations in the province achieved an output value of RMB 59.83 billion in 2024, a year-on-year increase of 32.3 percent. The company provides nearly 10,000 formal employment positions, with 13 percent being high-level experts, and has cumulatively added over 7,000 intellectual property rights.

Currently, NIO has established research and production facilities in over 10 locations worldwide, and has developed sales and service systems in 10 countries and regions including Europe, the Middle East, and the Greater Caucasus, serving customers across more than 350 cities globally.

Octillion is a leading energy storage company that specializes in designing and manufacturing battery storage systems for major industries focused on electrified product lines.

Win-Win Chains

Complete vehicle manufacturing reflects the systematic evolution of China’s intelligent manufacturing, consolidating the collective advancement of the entire industrial chain. The congregation of thousands of core component enterprises in the province has greatly improved the resilience of the supply chain in Anhui’s new energy vehicle industry.

Octillion Energy Holdings, which is focused on power battery system for NEVs, relocated from Silicon Valley in the U.S. to Anhui in 2009. As of April 30, 2025, it had manufactured over two million power battery systems for approximately 60 electric vehicle manufacturers.

“What others do not want to do or cannot achieve, we can accomplish with ease,” said Wang Jie, assistant general manager of Octillion. This confidence is derived from the expertise accumulated through the company’s persistent research and development efforts. Its self-developed Bipolar Encapsulated Structure Technology, or BEST, ensures that the battery pack does not ignite after a cell explosion. Meanwhile its Multifunctional Unitized Structure Technology, or MUST, stands out in the industry for its cost advantages, distintive design, and high level of integration.

Currently, the company has applied for 1,523 patents in core technologies such as mechanical structures, thermal management, and software and hardware, and has obtained authorization for 235 invention patents.

Compared to traditional gasoline-powered vehicles, NEVs place higher demands on digitization and intelligence. From fast charging to ventilation systems, and from battery management to autonomous driving, a NEV can be equipped with hundreds of intelligent sensors to monitor information and collect data, providing massive amounts of data to the entire Internet of Things.

“There are many fields for sensor applications and a wide variety of sensor types; however, the individual output value is very small. This limits the development of many research and development enterprises,” said Tao Guangsheng, chief of the Bengbu Economic Development Zone in Anhui, known as China Sensor Valley.

Huaxin Micro-Nano Integrated Circuit Co., Ltd., located in the valley, addresses these problems. Its independently developed intelligent production line for eight-inch micro-electromechanical system (MEMS) can achieve mass production, while another six-inch MEMS production line can conduct pilot and small-scale tests at a low cost. These two production lines, along with various technical processes, effectively solve the challenges faced by the smart sensor industry, especially the disconnection between research and production.

As one of the driving forces behind the development and innovation of sensor technology in China, the China Sensor Valley has established a comprehensive industrial ecosystem spanning research and development, and end applications. It was recognized as one of the top 10 MEMS sensor parks in the country in 2024. Its output value is projected to surpass RMB 30 billion by 2027.

According to Liu Wenfeng, deputy director of the Anhui Provincial Development and Reform Commission, the province currently has seven complete vehicle manufacturers, along with more than 3,000 large auto parts companies and over 1,700 aftermarket enterprises. This has resulted in a comprehensive industrial chain for NEVs that covers key aspects such as complete vehicle manufacturing, components and parts, sales, maintenance, and recycling.

NIO’s factory in Hefei, Anhui Province, is one of the most advanced factories worldwide in terms of intelligence.

.jpg) Influential Industrial Cluster

Influential Industrial ClusterNIO sells half of its vehicles in the Yangtze River Delta region, with vehicles being transported from Hefei, capital of Anhui Province, which is located in the region itself, thus shortening the time to market. Additionally, about 90 percent of its key component suppliers are located within a radius of 500 kilometers around its factory, which significantly reduces NIO’s overall logistics costs compared to its competitors.

“The logistics cost saving of several thousand yuan for each vehicle means that if one million vehicles are sold annually, tens of billions of yuan can be saved, and the market response speed will also be faster,” Li Bin said, adding that with policy support, the combination of technological innovation, industrial aggregation, geographical advantages, and latecomer advantages has propelled Anhui’s NEV industry to rapid progress, making it a global hub for smart NEV innovation and production.

The revenue of enterprises along the automotive industry chain in Anhui exceeded RMB 1.5 trillion in 2024, maintaining a growth rate of over 20 percent for two consecutive years. Anhui's NEV production has increased from 105,000 units in 2020 to 1.68 million units in 2024, representing a remarkable growth of 15 times.

“Anhui has always regarded innovation as the core driving force for upgrading the automobile industry and achieving high-quality development,” Liu Wenfeng said. Anhui has established a strategic advisory committee for the construction of an NEV industrial cluster, created a high-level innovation platform, pursued breakthroughs in key common technologies, and made plans for forward-looking technologies. Besides, it promotes the deep integration of government, industry, academia, research, finance, and service to accelerate the application of scientific and technological achievements.

According to Han Zhen, secretary-general of the Anhui Automobile Chamber of Commerce, the automotive industry, particularly the NEV sector, is a prime example of Anhui's integration of technological innovation and industrial innovation.

Anhui has been continuously making efforts in building an industrial ecosystem and is actively creating integrated industrial platforms and consumption scenarios. For example, the 2024 Hefei International New Energy Vehicle Exhibition attracted over 90 domestic and international brands and achieved total sales of approximately RMB 3.7 billion over five days. In addition, there is a gradual coordination of the entire lifecycle of automobiles, innovatively creating new scenarios and new business models for NEVs.

According to Liu Wenfeng, Anhui will accelerate the development of an internationally influential NEV industry cluster, contributing to China’s transition from a large producer to a leader in the automobile industry.