Shanghai is blazing a new development track powered by dual engines: one is intelligent manufacturing empowered by cutting-edge technologies, and the other is green development driven by low-carbon and energy-saving solutions. On September 10, China Today visited two enterprises in Shanghai – Shanghai Schneider Electric Industrial Control Co., Ltd. and Huaqin Technology Co., Ltd. – to observe firsthand how global investment and local innovation are jointly shaping Shanghai’s future of high-quality development.

An inside look of the Schneider Electric’s factory located in Putuo District, Shanghai.

Technology Empowerment

Inside Schneider Electric’s factory in Putuo District, Shanghai, rows of automated production lines manufacture components including AC contactors, circuit breakers, and thermal overload relays. Nimble robotic arms assemble, test, and package products with precision, and production data appears on large screens in real time showing the factory’s streamlined management processes. Robots shuttling through the aisles demonstrate how “intelligence” is embedded in this world-class “lighthouse factory.”

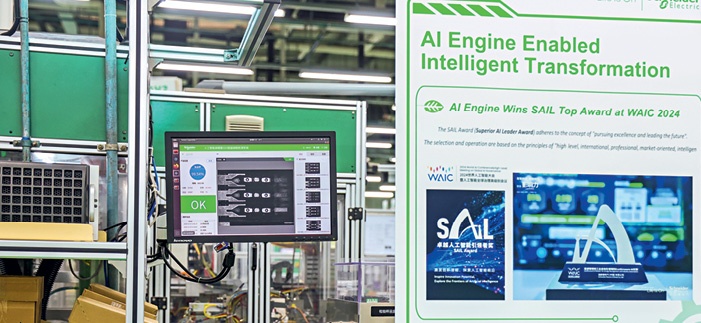

In recent years, the application of AI technology in industriy has become a focal point of global attention, and Schneider has also been making continuous efforts in this field. At Schneider’s Putuo factory, the reporter observed a vision inspection system powered by AI. A staff member explained that the system can efficiently and accurately conduct comprehensive quality control of products.

This is just one example of Schneider’s integration of 5G, AI, and big data across its production ecosystem. According to Mao Feifei, general manager of Shanghai Schneider Electric Industrial Control Co., Ltd., its product development cycles have been cut by an average of 63 percent through machine learning-based prototype testing platforms; equipment reuse has increased by 85 percent thanks to its third-generation automated modular flexible production lines which can switch lines based on orders; maintenance time has been reduced by 30 percent by combining AR technology with Large Language Models (LLMs); and supply chain efficiency has been enhanced by adopting AI-supported end-to-end management systems that link upstream and downstream partners.

For Huaqin Technology, a global intelligent product platform enterprise, the transformation from “China manufacturing” to “China intelligence” defines its evolution. Huaqin Technology provides global tech brands with end-to-end services from product development to manufacturing. Its products and services reach over 100 countries and regions worldwide, including smartphones, tablets, laptops, smart wearables, IoT (intelligence of things) devices, data center products, and automotive electronics.

In its showroom, reporters learned about Huaqin’s X-LAB, a forward-looking research institute. Staff explained that X-LAB has built five core labs dealing with acoustics, optics, thermodynamics, radio frequency, and simulation, and has initiated research into humanoid robot technologies, building a “general technology + future industry incubation” framework.

Huaqin’s proficiency in general basic technologies enables the company to react promptly to market demands. “For instance, the VR and AR products which are popular now require optical technologies,” said Yu Fang, senior director of securities affairs at Huaqin Technology, adding that “Our researchers are able to provide technical support to any needs that our clients raise.”

So far, X-LAB has developed multiple groundbreaking technologies – MetaBass bass enhancement, open-ear audio systems, in-car AR-HUD systems, and AI vision inspection algorithms, among others. Looking ahead, this lab will continue to strengthen its reserve of product-oriented technologies to ensure that Huaqin maintains its leadership in frontier technology.

Green Growth

Against the backdrop of global climate change, green development has become a vital requirement for corporate transformation. Whether multinational or local, those who achieve “green acceleration” will reap the dividends in future development.

“Schneider Electric has incorporated sustainability goals into its main strategy. We work with our partners to jointly advance carbon neutrality through technology,” said Mao. In China, Schneider Electric operates 15 factories certified by the Ministry of Industry and Information Technology as “green factories,” along with 21 “zero-carbon factories,” continuously delivering green innovations to both domestic and global markets.

During the second quarter of 2025, Schneider Electric helped customers cut 734 million tonnes of carbon dioxide emissions. At the same time, the company’s supply chain decarbonization efforts have made significant progress. Through its “Zero Carbon Project,” Schneider Electric has assisted nearly 1,000 global suppliers in achieving an average of 48 percent emissions reduction.

The company is also expanding its emission targets from its own operations to the entire value chain. Its blueprint sets the goal of achieving zero-carbon operations by 2030 and net-zero across the entire value chain by 2050.

Huaqin Technology has announced similar ambitions. According to He Xiangfeng, director of Huaqin’s ESG Executive Committee, the company has committed to hit peak carbon emissions by 2030 and achieve carbon neutrality by 2050, with a targeted three percent annual reduction in carbon intensity.

“To achieve these goals, we have taken multiple measures,” He explained, adding that “For example, we are actively adopting green electricity. Photovoltaic panels are installed on the rooftops of our facilities to provide clean energy, and we also purchase renewable power from the grid. The share of clean energy in our production is steadily rising.”

AI technology is integrated into multiple stages of Schneider Electric’s production process.

Future Oriented

Since entering the Chinese market in 1987, Schneider Electric has steadily expanded its presence in China, which has thus become its second-largest market globally, as well as one of its major R&D bases.

Mao Feifei emphasized that the company’s success in China is inseparable from its location in Shanghai whose advantages in supply chains, talents, and supportive policies have been crucial. He explained that “Shanghai houses numerous industrial bases, and their supply chains center on the Yangtze River Delta. This means that many of our suppliers can deliver raw materials once or even twice a day. Meanwhile, our R&D hub in Zhangjiang (in Pudong New Area) ensures a continuous influx of innovative talent.”

He added, “We can see that the local government provides us with great support – for instance, this year our Putuo factory partnered with the Shanghai Municipal Commission of Economy and Informatization to further advance smart manufacturing, backed by favorable industrial policies.”

“For Huaqin, developing in Shanghai means both safety and confidence,” said Li Yan, the company’s senior director of public affairs, stressing that “This metropolitan is a global hub of information and talent, which is vital for an R&D-driven company like ours. In recent years, the local government has also rolled out new policies in attracting investment, for example, by offering subsidies, especially talent incentives, for leading enterprises and small and medium-sized businesses. From Shanghai, we can serve global clients and access international markets, which provides continuous momentum to our innovation.”